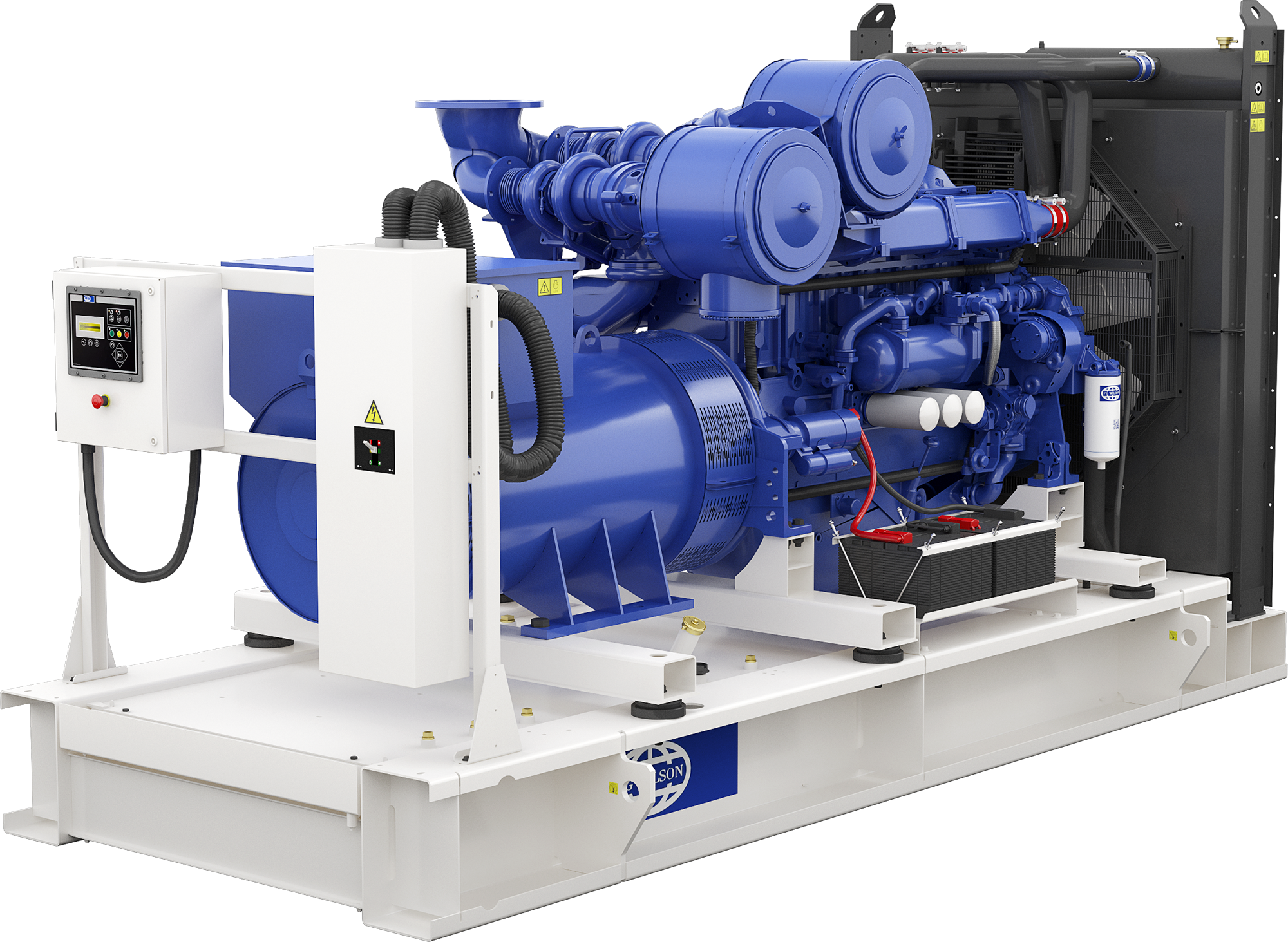

You have just bought an FG Wilson generator set and installed it in accordance with the manufacturer's standards, i.e. on a concrete base, with a space of at least 2 m around it, with correctly sized cables and with an automatic inverter.

To protect your investment, you need to ask yourself how it should be maintained and used.

An effective and regular maintenance programme will ensure a long service life for the generating set. This maintenance should only be carried out by qualified technicians. Keep the maintenance reports, they will make future work easier.

In general, keep the unit clean. Remove any deposits of fuel, oil or other products from inside or outside the unit, as well as from or near the sound insulators. Clean surfaces with an aqueous industrial cleaner. Do not use flammable solvents for cleaning.

Any acoustic insulation with a protective coating that is worn or perforated must be replaced immediately to prevent oil or other products from accumulating in it.

Contact a qualified technician for details of preventive maintenance.

Here are a few recommendations:

Battery maintenance

Batteries contain hazardous materials and in the charged state, each cell contains lead (Pb) electrodes and lead (IV) dioxide (PbO2) immersed in a sulphuric acid electrolyte (H2SO4) at 33.5 % m/m (6 molar). In the discharged state, the two electrodes form lead (II) sulphate (PbSO4) and the electrolyte releases sulphuric acid dissolved in primary water.

Disposing of batteries on landfill sites is therefore harmful to the environment, and burning batteries gives off polluting fumes.

Batteries are an essential part of the generating set and must be properly maintained. Keep the battery installation area clean and dry, and ensure that any cap vents are tight (if fitted).

Clean the battery case with one of the following cleaning solutions:

- A mixture of 0.1 kg (0.2 lb) baking soda and 1 L (1 qt) fresh water

- A mixture of 0.1 L (0.11 qt) ammonia and 1 L (1 qt) fresh waterRinse the battery case thoroughly with fresh water.All battery connectors must be clean and tight. Use fine-grit sandpaper to clean the terminals and cable fasteners. Clean these items until the surfaces are shiny. Do not remove too much material. Excessive removal can cause a poor connection between the clamps and the battery terminals. Apply grease or other terminal protectant to fasteners and terminals to prevent corrosion.

The electrolyte level should cover the plates/grids (13 mm / 1/2 inch) inside the battery to maximise transfer at full charge. If the liquid level is below the plates/grids, add only distilled water; never add battery acid to top up, as this will destroy the grids.

It is recommended to check the electrolyte and the condition of the batteries every 500 hours of operation. In high ambient temperatures, it is recommended that you use temperature compensation and check electrolyte levels more frequently, for example every 200 hours of operation. These checks should also be carried out as part of your routine maintenance inspections.

The recommended fluid level is approximately 13 mm (1/2 inch) above the plates or approximately 3 mm (1/8 inch) below the bottom of the filler tubes coming down from the port openings. If the fluid level is within these recommendations, replace the port caps and recheck after three months.

Preventive maintenance programme

Depending on the application of the generating set, preventive maintenance requirements will vary.

Warning:

- Enclosures fitted with door closers or swing doors (where applicable) must not be opened when the wind is blowing at more than 20 km/h.

- Engine maintenance intervals may need to be more frequent than those indicated in

this section. Please consult your local distributor for the maintenance instructions that apply to your engine.

- Operators should only carry out the pre-start checks described in the Control System - Section 5.

- The following procedures should only be carried out by a qualified technician.

Daily or every time you start up:

(For emergency generators, these procedures can be carried out weekly). A general inspection should be carried out daily and before starting the engine. The pre-start checks described in Section 5 should be carried out during this general inspection.

Every 2 weeks:

(For emergency generators that have not been started.) Carry out a functional check of the generator, starting it up and leaving it running for just 5 minutes.

Every month :

(For standby generators which have not operated under load). Carry out a functional check and a load check of the generating set, by starting it up and allowing it to run at 50 % load for at least 1 to 2 hours.

Drain water and sediment from the fuel tank - Fuel tanks can be drained from below, using a drain plug or drain cock (if fitted), or by connecting a hand pump to the fuel filler pipe or tank access port. Dispose of the water properly.

Drain the outer section of double-walled tanks - In double-walled tanks (where applicable), the outer section must be drained by connecting a hand pump to the rear access socket located behind the generating set. Properly dispose of collected liquids.

Warning:

Do not run a diesel engine at low load for a long period of time.

Every 12 months or 500 hours :

Repeat the daily verification procedure, with the addition of :

1. Check all the safety devices in the control system, simulating faults electrically.

2. Clean all battery cap vents.

3. Retighten all the exhaust fittings.

4. Tighten all the electrical connections.

5. Start the engine and check on the control panel that all the instruments and meters are working normally.

Preventive maintenance of the alternator

No periodic maintenance is required for the alternator, but please observe the following recommendations.

- Periodically inspect the condition of the alternator windings and carry out a general cleaning.

- Periodically inspect the cable connections between the alternator and the circuit-breaker.

- Consult your local dealer and the alternator manual.

- Preventive engine maintenancePlease consult your local distributor for specific maintenance instructions concerning :

- Daily start-up checks

- Weekly checks

- Maintenance schedules - only qualified technicians can handle them

Engine maintenance schedule

If necessary

- Battery - Replacement

- Battery or battery cable - Disconnection

- Engine - Cleaning

- Air filter element (dual element) - Cleaning/replacement

- Engine air filter element (single element) - Check/replace

- Fuel system - Priming

- Difficult application - Control

Every day

- Cooling system level - Check

- Conducted equipment - Control

- Air filter - Checking the clogging indicator

- Engine air prefilter - Checking/cleaning

- Engine oil level - Check

- Primary fuel filter/water separator - Draining

- External checks

Every 50 hours - service or every week

- Fuel tank - Draining

Every 250 service hours or every 6 months

- Alternator and fan belts - Checking/adjusting

Every 500 service hours

- Fuel filter - Replacement

Every 500 service hours or every year

- Battery electrolyte level - Checking

- Cooling system additive - Control/ top-up

- Air filter element (dual element) - Cleaning/replacement

- Engine air filter element (single element) - Check/replace

- Engine oil and filter - Change/replacement

- Hoses and clamps - Inspection/replacement

- Radiator - Cleaning

Every 1000 service hours

- Alternator and fan belts - Replacement

- Engine valve clearance - Checking/adjusting

- Turbocharger - Control

Every 2000 service hours

- Intake cooler wiring harness - Inspection

- Alternator - Control

- Crankcase breather - Replacement

- Motor anchors - Checking

- Starter - Control

Every 3000 service hours

- Cooling circuit thermostat - Replacement

- Injector - Test/replacement

- Water pump - Control

Every 4000 service hours

- Intake cooler wiring harness - Cleaning/testing

Every 6000 service hours or every 3 years

- Coolant (heavy commercial use) - Oil change

Every 12,000 service hours or every 6 years

- Extended life coolant - Oil change